2026 Top Cargo Container Innovations You Should Know About?

In the rapidly evolving world of logistics, cargo containers play a pivotal role in global trade. Industry expert John Mitchell, a leading figure in cargo container innovations, once stated, “Innovation in cargo containers is essential for sustainable growth.” This sentiment underscores the importance of exploring the latest advancements that redefine how cargo is transported.

The year 2026 promises to bring groundbreaking changes to cargo containers. Smart technology is becoming standard, enabling better tracking and management of shipments. Consider the integration of IoT devices that can monitor temperature and humidity levels inside containers. Such innovations can prevent spoilage and enhance supply chain efficiency.

However, the industry faces challenges in keeping up with these innovations. Many companies struggle to adopt new technologies promptly. The need for training and adaptation can slow down progress. As we examine the top innovations in cargo containers, it is crucial to reflect on not just the benefits but also the potential barriers to implementation. Change is necessary, but it requires a willing mindset to embrace it.

Revolutionary Design Features in 2026 Cargo Containers

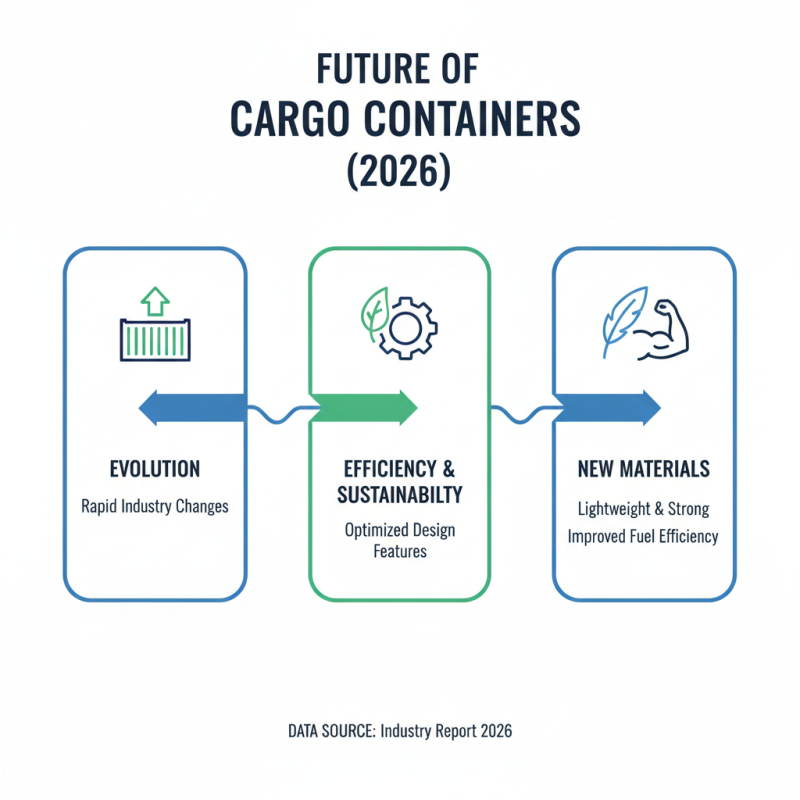

The cargo container industry is evolving rapidly. The design features of 2026 containers focus on efficiency and sustainability. New materials reduce weight without sacrificing strength. This change enhances fuel efficiency in transport vehicles.

Containers now include smart technology. Sensors monitor conditions inside them. This improvement ensures the safety of goods during transit. Advanced tracking systems provide real-time data. Shippers can respond quickly to challenges.

Consider implementing best practices for using these innovations. Regularly check sensor functions. Ensure your cargo is compatible with new container designs. Adapt your logistics to fully utilize these features. Effective usage can minimize waste. While these innovations are promising, they also require careful management. Reflect on how these changes impact your operations.

Smart Technology Integration for Enhanced Logistics Tracking

The logistics industry is rapidly evolving, driven by smart technology integration. Enhanced tracking systems are at the forefront of this evolution. With sensors and IoT devices, real-time data collection becomes possible, allowing for precise location tracking of cargo containers.

One notable advancement is the use of GPS tracking. This technology provides details on the exact position of shipments. It helps prevent loss or theft, which are common issues in the logistics field. However, not all systems are foolproof. Occasionally, GPS signals can fail, or data may be misread. Logistics companies must continuously improve these technologies to minimize such risks.

Tips for better tracking: Invest in multiple tracking methods. Combining GPS with RFID tags can provide layers of data. Ensuring a backup system helps when one fails. Regularly train staff on new technologies. Knowledgeable employees can reduce errors and improve efficiency.

Integrating smart technologies can also enhance communication. Automated alerts notify stakeholders about shipment status. However, too many notifications can overwhelm staff. Finding a balance is essential. Data must be analyzed carefully to avoid overlooking important trends.

2026 Top Cargo Container Innovations You Should Know About

| Innovation | Description | Benefits | Expected Impact |

|---|---|---|---|

| IoT-Enabled Tracking | Integration of IoT devices for real-time cargo tracking and monitoring. | Improved transparency and reduced cargo loss. | Increased efficiency in logistics operations. |

| Self-Reporting Containers | Containers that can report their status and conditions autonomously. | Enhanced data accuracy and decreased manual checks. | Significant reductions in operational costs. |

| Blockchain for Logistics | Use of blockchain technology for secure, decentralized transaction records. | Improved security and reduced fraud. | Streamlined supply chain processes. |

| Smart Container Monitoring Systems | Advanced sensors and systems for cargo condition monitoring. | Safeguards cargo quality during transit. | Reduction in spoilage and damage claims. |

| Automated Container Handling | Robotic systems for loading and unloading cargo containers. | Increased efficiency and safety during handling. | Faster turnaround times at ports. |

Sustainable Materials and Eco-Friendly Innovations in Containers

The shipping industry is at a crossroads, driven by sustainability. A recent report predicts that by 2026, eco-friendly containers will dominate the market. Companies are innovating with sustainable materials. For instance, bioplastics are now being used to create lighter and stronger containers.

These materials reduce carbon footprints significantly. According to industry data, bioplastic containers can cut greenhouse gas emissions by up to 70% compared to traditional options. Innovations such as recyclable containers and modular designs are also emerging.

Modular containers allow for easy repair and reuse, minimizing waste in the supply chain.

However, challenges remain. Many sustainable materials still have durability issues. There’s also a lack of recycling infrastructure in some regions. The industry must address these gaps to fully realize the potential of eco-friendly innovations. Collaboration among stakeholders could accelerate positive changes.

Automation and Robotics: The Future of Cargo Handling

Automation and robotics are transforming cargo handling and logistics. According to a recent report, automation can enhance efficiency by up to 30%. Automated systems reduce manual labor, speeding up operations. Robotics can handle heavy loads and repetitive tasks, allowing human workers to focus on strategic roles. In ports and warehouses, this technology is becoming essential.

However, challenges remain. High initial investment costs can deter companies from adopting these innovations. The integration of robots into existing systems may encounter compatibility issues. Additionally, workforce training is crucial to ensure employees can effectively work alongside machines.

Tip: Companies should start small, piloting automation projects before full-scale implementation. Assessing workflows helps identify areas where robotics offer the most benefit.

Another important consideration is maintenance. Automated machinery requires regular servicing to avoid costly downtime. A proactive maintenance approach is key to maximizing equipment lifespan.

Tip: Develop a scheduled maintenance plan to keep automated systems running smoothly. Engaging with employees in this process can yield valuable insights.

Security Enhancements in Container Transport for 2026 and Beyond

The logistics industry is evolving rapidly, particularly in the realm of cargo container security. By 2026, new innovations will reshape how we think about transporting goods safely. Advanced technologies will enhance the integrity of containers, ensuring they remain secure throughout their journey. One emerging trend is the use of smart locks that utilize biometric access and real-time monitoring. This could greatly reduce tampering incidents.

However, these advancements are not without challenges. Implementing complex security systems may require significant investment and training. Some industry players may resist these changes, fearing disruption to established processes. Despite the benefits, these obstacles need careful consideration and planning. We mustn’t overlook the importance of human oversight. Automated systems can fail, and human judgment is still essential in real-world scenarios.

Moreover, cybersecurity will play a crucial role in securing data related to container transport. Containers equipped with IoT devices will generate vast amounts of data. Protecting this information from breaches is paramount. The intersection of physical and digital security can create vulnerabilities. As we move forward, finding the right balance will be key to ensuring safety in container transport for 2026 and beyond.

Related Posts

-

Top 10 Best Sea Container Options for Shipping and Storage in 2023

-

Why Freight Shipping is Essential for Your Business Growth

-

Top Tips for Choosing the Best Freight Forwarder for Your Shipping Needs

-

2025 Top Trends in Air Freight Shipping You Need to Know About

-

Top Freight Carriers of 2025: What You Need to Know for Shipping Success

-

2026 Best Trucking Companies to Consider for Your Shipping Needs?

Crescent Textile Solutions

Fax: (920) 793-3818